I have spent so much time on the brake system that I can do it drunk, and in sleep. There are common issues I have faced with factory floating calipers, ABS.

Fundamentals

You would be surprised, but there are many that refuse to understand how brakes work. Brakes convert kinetic energy into heat.

“If it ain’t dusting, and eating pads/rotors – it doesn’t brake !!!”

Warning

If you are a spirited driver, you shouldn’t use factory brakes in first place. Usual floating caliper brakes cannot handle 700 °C. I have wrecked enough calipers, and tried to refurbish them…pointless.

Of course, if you cannot brake race-style do not worry. I have annually worn ~1’000 € in brake pads/discs. That was a mix of tourist/pro stuff.

Imagine proper brakes – my friend used to have Seat Cupra R with Brembo performance pack. Great duner‘s car, one visit of Brno Circuit, and overheated brake pads needed some repairs.

Bell system Brembo brake discs…it just needed better pads. I paid for a set of race pads 700 £. How much for Seat? I bet double. I just wanted a fun for poor 😉

Time & life saver

Give yourself a favour, and stop buying “cheap” shit – poor man always pays twice – high-quality products, proven by racing, are cheap !!!

If you just bought a used car, stop wasting your time and do the following:

- Always buy original OEM parts, or battle-proven racing stuff from Ferodo (inventor of brake friction materials), Brembo or Pagid (known racing stuff). I never had issues with original stuff from ATE, or above by race corps. But I have experienced many failures of cheap crap.

- Stop seeking the holy grail – if it ain’t dusting, it doesn’t brake.

- Racing/hobby stuff – without datasheet, manufacturers hide something…and usually sells only crap. I wanna see a nice table of friction coefficient vs temperature.

- Don’t push your “luck” – OEM/ATE, Ferodo Premier pads handle some grilling…they will fade under heavy braking, and there is high probability it may fail when you need it least !!!

Family stuff handles 300 °C, with 500 °C for few seconds until they fade, and friction material burns. I recall some road-legal speed chase on “James Bond’s” Furka Pass mountain road.

A kamikaze guy (you hear me, they race to the death no matter what…and they will take you with them…YOU HAVE BEEN WARNED, nothing makes SPSers madder than being smarter) with SCRC car tried to flee from Hilda HR I…two corners later a burning feeling in my A/C – that is where you know, you have to overtake/overbrake.

Trust me, you won’t win road-racing with factory stuff 😉 Ferodo DS2500 can take some beating, stock brakes overheat in less than 5 minutes.

Ever wondered why all alpine roads have 50 km/h speed limit? Glocknerstrasse is a popular place for car manufacturers – they have hooked up various sensors on car, and slowly driver downhill. - Replace worn brake hoses – best solution is braided brake hoses from Hel Performance. Nothing makes you madder than spongy brake pedal, and hoses sucking ambient air/water.

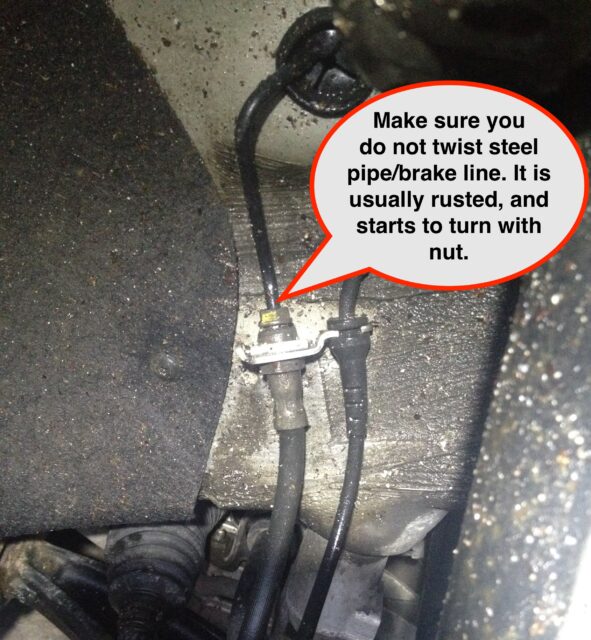

Make sure you do no damage to brake lines. Rusted brake line adapter between hose and steel line tends to turn with nut. I have twisted steel pipe, and wondered why is left brake calliper always stuck!!!

Watch out for damage to brake line if you replace brake hoses. - Replace brake fluid – best solution is Castrol React SRF Racing brake fluid, used by Škoda Motorsport for example, and many other racing teams. It amazingly recovers from overheating, where normal brake fluids boil, and become useless.

- Consumables – only in Hollywood movies everything lasts forever, and needs no replacements. It is recommended to replace brake fluid every two years.

Before I started to use racing stuff, I have replaced brake fluid 2-3 times per year (every 10’000 km because it boiled many times, and didn’t work any more than suppose to). - Check out the handbrake cables, and adjust it accordingly. VAG OEM rear calipers are the major cause of all issues with rear brakes. Those handbrake levers must return to its initial position; otherwise, rear brakes will permanently brake.

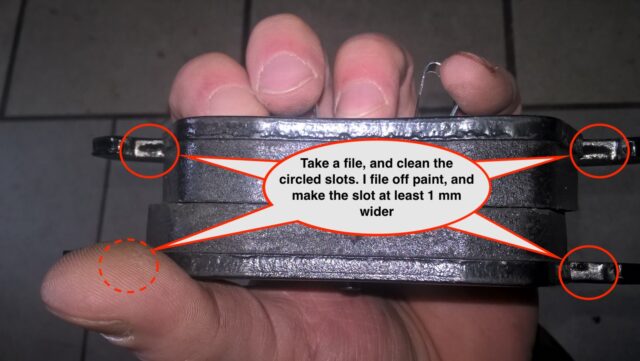

- Proper installation of pads – check out images above, and below (click to enlarge). No matter what, everything will have surface corrosion in no time. That eventually leads to so-called “sticky” pads. Especially, if you have usually 500 – 700 °C on brakes…one month later all will be rusty, and eventually get stuck. I always remove paint from pads, and rust from brake caliper carriers. Replace metal clips for guiding brake pads.

Symptoms

- Poor brake performance

- Spongy/soft/sinking brake pedal

- “Sticky” pads/Overheating/Stuck calipers/Stuck pistons/Uneven braking performance

- Warped pads/discs

- Brake balance

Symptoms & Solutions

Read “Time & life saver” above by because it resolves most of the issues written below!

Poor braking performance

Assuming you have read carefully “Time & life saver” guide. There are possible issues:

- Overheated, and burnt brake pads – stock brake pads are designed for cold-bite-braking. In other words, they brake always same from 0-300 °C. If you live in mountains, one trip 10 km downhill, and your brakes are cooking/overheated. Brake pads burnt with glass like coating on surface. It usually runs 1 mm deep under surface, and needs to be milled or grind off before it brakes again.

Racing pads easily handle 500 – 700 °C, and start to fade off only under heavy downhill braking. It was always fun how desperate duners tried to flee from Hilda…once, you get that burning feeling from A/C (assuming, it is not you who overheated brakes), you “attack”, and overbrake/overtake that poor fool 😉

Spongy, soft or sinking brake pedal

We start from your cockpit, where you feel brake issues immediately.

Your brake pedal (with ignition off) must be hard to press, hard as stone, once you press it down. If you keep pressing it as hard as you can, it must stay at one place.

My brake pedal usually stayed in 1/3 of its travel (between upper position, and the floor). I like it short, race style – if you must press the pedal right to the bottom, and it starts to brake 5 cm from the floor…there is something horribly wrong, and also very dangerous for you.

!!! NO BRAKES = NO LIFE !!!

While driving (brake booster assisting your driving), the brake pedal supposes to brake right from the top of travel. The more you press, the more it brakes.

Before you start, make sure ignition is off – we are not interested in brake booster right now.

Common issues, you don’t even notice (because nobody told you, it is damaged/faulty/misadjusted):

- Spongy pedal – air in brake lines, ABS pump, or both; worn/weathered brake hoses (soft connection between steel brake lines, and wheel/caliper) sucking air/water; over-boiled/old stock brake fluid.

- Soft pedal – no idea what is the difference between soft, and spongy. Most likely same, and the above by applies.

- Sinking pedal – brake fluid is not compressible (at least unnoticeable without precise measuring tools), and the only thing that can partially compress is trapped air bubbles in brake lines.

If you have bled brakes right now, and your pedal still sinks…there is a leak (brake hoses, caliper seals/o-rings, brake cylinder o-rings, ABS pump, adapter for connecting front/rear brake lines underneath the car)

"Sticky" pads/overheating/stuck calipers/uneven braking performance

The first sign that nobody misses, is each wheel brakes differently. During heavy braking, my car pulled me sideways (stuck left brake caliper)…or rear end of the car started to dance (stuck left-wheel hand brake cable).

You won’t even notice…unless you accidentally check out your new alloy rims over winter, and there is weird warm air/smoke coming from your brakes. In most extreme cases, it may look like this.

- Brake pads are worn, and brake pistons usually get stuck at the end of travel.

- Poorly installed brake pads (read “Time saver”).

- Damaged dust seal around the brake caliper piston – if you find out, the seal torn apart, just buy the new. Trust me, refurbish/replacement of seal rarely works (I have tried many times, it is more time wasted than money saved).

If you are bored, and have lots of spare time – you can try to repair it. Get new caliper refurbish kit (dust seal, o-ring, and new cylinder/piston – unless you have lathe, and capable to turn/grind rusted/damaged piston), and refurbish whole brake caliper.

I tried once, it rarely works. Once, the dust seal is damaged, the piston is rusted inside, and doesn’t move freely. In my case, also whole caliper/piston most likely deformed by excessive heat.

Refurbishing takes at least 2 hours * usual 20€/hour salary – 40€ + >30€ refurbish kit…70€ for Russian Roulette.New or professionally refurbished brake caliper costs ~100€.

It is a no-brainer, bin that shit off, and buy a new one. Trust me, it saves you lots of time/resources !!!

I had countless issues with stock floating calipers…they deform due to high temperatures. Once, heat deforms the caliper body, pistons get stuck. I tried to refurbish…pointless.

So-called Big Brake Kit for VAG cars from VBT guys costs around 2’000 £. I was never crazy enough to spent 2’000 on 5’000 £ car 😉 Replacing all stock calipers every 30’000 km for 500€ was the simplest solution.

I already had issues with MOT guys, and mine rally suspension setup. Explaining why I have >312 mm brake discs, and weird fixed calipers was beyond my mental, and wallet capacity.

Warped/deformed pads/rotors (floating calliper)

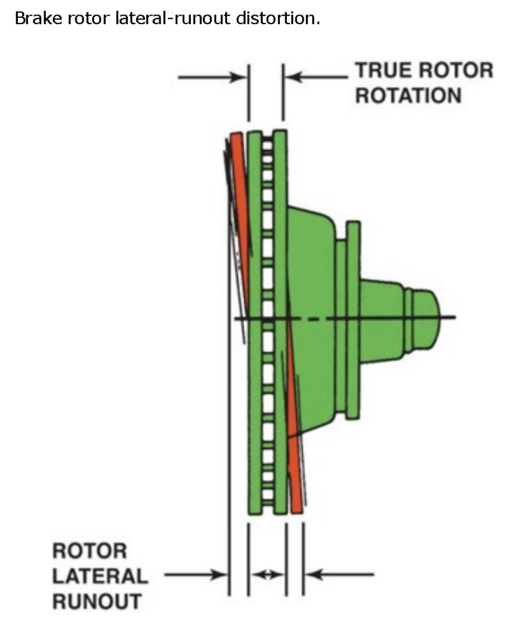

Let’s define the meaning of “warped” – mostly it is known as deformed from its original flat/straight shape. But warped how?

I never had warped/deformed brake rotor, and my brakes suffered heavy grilling regularly. Seriously, stop “saving” money on “cheap” shit.

Only time, you may have warped high-quality rotors is rotor thickness below allowed minimum. Replace the rotors.

You will always have warped pads on floating calipers. Even fixed race calipers will never ever brake evenly. It is impossible if you understand design of calipers.

You will always have lateral warp because caliper always deform less at the top, than at the bottom. Try to squeeze something with your hand – you have more power in the palm than at the end of the fingers.

You will always have unevenly worn brake pads on floating calipers because there is only one piston. Piston side brake pad have more pressure, and will be ground faster.

I regularly removed racing pads from the car, and milled them even again. Of course, stock pads are cheaper to replace. It costs like 50€…I bothered about 400€ racing brake pads.

I have never had warped brake rotors. I have heard stories from my friend that regularly had issues with warped discs. I usually had ~500 °C on brake rotors, even grilled red normal stock Brembo/Ferodo rear rotors, and they were like new…never distorted.

Only cheap crap non-OEM materials with questionable quality can deform just by looking at them. What sane person buys, and installs such a shit on car is beyond my understanding.

!!! NO BRAKES = NO LIFE !!!

But there was a time, where my brake caliper got stuck, overheated pads – once, pads started to melt, friction material was deposited on rotor. Every braking was accompanied by shaking of the whole car.

With OEM, or high-quality replacement, you will never ever have warped rotors…PERIOD.

It reminds me the old climbing wisdom.

“Do you know what is the benefit of cheap gear/equipment? It lasts until the end of life.”

Warped/deformed rotor (fixed calliper)

If your rotor warps, make sure the calliper is properly installed. It may be pushing the rotor sideways. Unsure, whether it is even possible on cars – only MTB bikes have possibility for lateral adjustments.

Of course, you may be at minimal rotor thickness, and it simply bends.

If you still have enough material on rotors, and your rotors are super expensive; you can re-machine them on a lathe.

Symptoms & Solutions for pilots

Whatever you do, you have to always suffer consequences. Cause/effect is bitch. No matter what you think/feel, it is always your fault…most of the time !!!

Brake balance

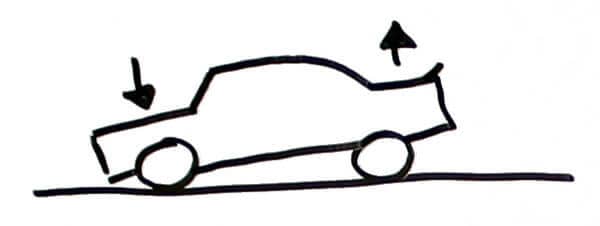

You just upgraded suspension, new shiny coilovers. Suddenly, front or rear brakes overheat. It brakes even worse than before. It supposes to brake better now because of ultimate grip from coilover/race-tires (assuming you swapped also arm bushes).

You just fucked up stock brake balance. I have been there, it took me months to “fix” it. First sign was ESP thinking car is in oversteer, and started to brake my rear wheels.

The second sign was rear brakes overheating. What I didn’t know back then how poorly Protlum guys designed the suspension – rear end of the car dropped too low, and the natural wedge between front/rear axles was almost flat.

During light braking, rear brakes did 60-80% of work instead of front brake bias. Owner of Protlum told me “it was designed for stock suspension replacement without any changes to stabilisators.”

Can you imagine how it worked without any adjustments?

I tried proportioning valve, different brake pads friction coefficient. I had to adjust my braking style…still, if it is fucked, it can’t be fixed. The only strategy that helped somehow was heavy nose-dive braking where you forced front brakes to do the job. Still rear brakes overheated more than front ones.

Assuming you know how to brake, and you cannot brake inside the corner – let’s repeat how braking, weight transfer works.

Do not confuse trail braking with braking

By braking, I mean max. brake pressure to stop the car or reducing speed before a corner. It is impossible to brake inside the corner, that is why ABS was invented in DTM golden era.

Common solutions for brake balance

- Different rotor sizes on front and rear axle.

- Different brake pad’s friction coefficient on front/rear end.

- Some cars may have two brake cylinders, and balance bar.

Optimal brake balance utilizes both brakes equally, with slight front bias (Family 1’400 kg cars usually have vented large rotors at the front, and solid discs at the rear end).

Be careful what you wish for!

Friction material deposits

Cause is simple, overheated friction material that sticks to brake rotor or mismatch of rotor/pads material.

If you like High-GNM fun, get proper tools for it. You cannot grill brakes with stock consumables. It is the quickest way to die!

Use proper brake pads that candle your usual brake temperatures. Drilled or slotted rotors to keep pads clean. And clean rotor slots/holes regularly.

ABS

ABS stands for Absolutely Boring Shit – it was designed for monkeys (sorry monkeys, I’m sure you would do better than most car users). Do you recall those times when our parents drove deadly, unsafe cars without any assistants?

I recall rally stages in mountains, snow on roads…in rare occasions my dad installed chains on tires…winter tires Barum were really crap back then, and there was not much winter road maintenance.

It was those romantic times when you broke a leg during skiing, the closest hospital was 2 hours of horrible pain/screaming in the car….because waiting for an ambulance took longer than driving yourself.

What is interesting, there were almost no accidents. BALLS was in place and there was still people.

Now? There is a lorry on the highway accompanied by 500 m traffic congestion with average speed 80 km/h because some poor fucker believes driving slowly around that lorry is safer… I do not know, I wanna get out of dead zone as soon as possible.

Rain, 1 mm of water on road, guess what we drive 50 km/h on highway…and most fuckers blocking left speed/overtaking lane.

Snow? Don’t get me started…nowadays, we have snow about a week per year split in 1 – 3 days “winters”. It is faster to walk… seriously. It is total traffic collapse.

What the fuck, what let those fuckers on the road in first place. If you shit your pants, and can’t drive…use the fucking train or bus.

Back in my instructor days, 1 from 100 failed a driving test for some stupid mistake…it seems to me that, 25 years later, even mentally challenged humanoids get a driving licence. Oh well, business is business.

Rage against the machine

There was a time when this ABS shit started to really piss me off. I simply switched off assistants – it is the illusion of safety for car users anyway. I know no better life-saving system than fear of death and BALLS.

It forces you to use the brain, what seems to be issues nowadays, as German scientists warned us back in 1930.

Problem is – and they warn you about it – once you get air inside the ABS, you will never get it out.

I do not know whether ABS unit leaked air, or was faulty…too much time already wasted, and those ABS parts are not cheap either. I simply made a brake splitter/adapter for even brake power distribution + proportioning valve.

Do not forget, we still deal with FRC cars. I liked friend’s Seat Cupra R though…great brake balance, racing ABS…it simply worked.

Rebuilding used family cars rarely works…just a simple rear stabilisator swap, and the whole ESP system is fucked.

Never found out how to set up ESP and ABS in ECU. There will be somewhere thresholds or hysteresis from yaw, abs sensors. If you can adjust for improved handling…it would be great…still prefer BALLS system, though.

The simplest solution is to revert to an old school mechanical brake system.

Seriously, switch ALL assistants off – it will save your life one day!

Repair & replacement guide

Do you want to be right, or do it right?

Bleeding brakes

There is the official way done by authorized services – they have a machine with four hoses connected to bleeding nipples. It pumps out brake fluid, while the technician fills up the brake fluid reservoir with fresh brake fluid.

The old school way

There is the old school way (VAG service manual) from analogue ages, which needs at least four hands, and one foot.

- Pump the brake pedal while all bleed nipples are closed.

- After some pumping (like 10 x or so). Hold the pedal down to keep pressure inside the brake system.

- Attach a silicon hose to bleeding nipple with a bottle on another end (for old brake fluid).

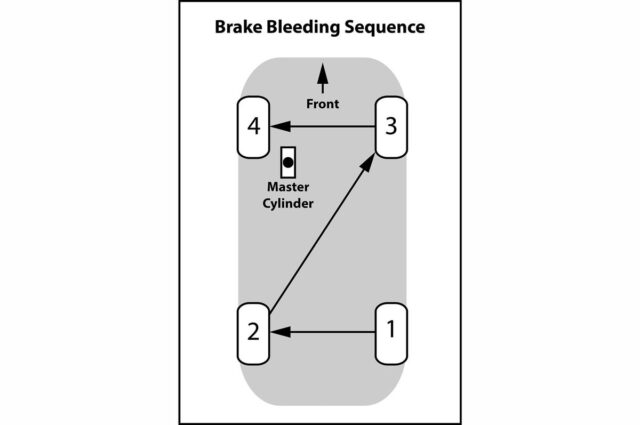

- Open the bleeding nipple of longest brake line first (usually RR aka rear right wheel).

- Close the nipple, and repeat step 2.

- Open the RL…and so on, until you are done with all wheels.

There is also the same old school procedure, but starting with the shortest brake line (usually FL aka front left wheel or FR if you are driving on the wrong side of road as some civs do ;-). I tried both, and I see no difference in results.

The gravity way

My master Caroll Smith taught me the easy way, that needs just two hands. It is basically the official way for rich.

All you need is 5 – 20 metres of silicon hose with inside diameter 3 – 4 mm (which fits tightly to bleeding nipple, and won’t easily slip/disconnect). It costs like 20 €.

And at least one bottle like PET from your mineral water. If you use four bottles for each wheel, you need less silicon hose. Choose your poison.

Attach hose(s) with bottle to 1 – 4 wheel(s), and open the bleeding nipple(s). Done. Only thing you need to watch is your brake fluid reservoir…NEVER GET IT EMPTY !!!

You can speed up process by gentle pumping of brake pedal.

If you have just replace brake calliper(s) – you will have to use the old way most likely because there will be lots of trapped bubbles inside the calliper.

I usually repeated the bleeding process with new calliper(s) because you will never ever bleed all bubbles anyway. New brakes usually 2-3 bleeding procedures. Bleed first time…grill the brakes…pressure, and heat sorts out most of your problems.

Rinse, and repeat the gravity bleeding process.

Of course, if you still have air after 3 – 4 bleeding processes… there is something wrong like worn brake hoses or damage lines. I told you so in “time & life saver” !

Brake pads replacement

In the good old days, every man could replace worn brake pads or engine oil. In modern days, fraumen can only call the road assistance while doing make-up inside the car.

Buy the pads, and brake rewind/push tools. It is cheaper than your authorized car service, and most importantly, you will sleep like a clueless baby without any worries what someone fucked up.

You already have tools for bleeding brakes. Process is simple:

- Remove the wheel… just in case you are a very bright, ambitious mechanic.

- (OPTIONAL) Connect hoses with bottle, and open the bleeding nipple slightly.

- (OPTIONAL) If your rotors are already slightly worn, the brake caliper will be hard to remove. Use a screwdriver to push brake pads back slightly to easily remove the whole caliper. Gentle love from hammer/crowbar is also my favourite solution.

- Remove the floating calliper.

- Connect hoses with bottle.

- Open the bleeding nipple slightly.

- Use the push/rewind tool shown above by.

- Front VAG floating callipers are pushed.

- Rear VAG floating callipers are rewound either to the left or right.

- Close the bleeding nipple, remove hose with bottle.

- Clean everything from rust, oil as suggested in “Time & life saver” section.

- Replace the pads & install the calliper back to brake carrier.

Brake callipers replacement

Procedure is same as “Brake pads replacement” with some HR extra. Once, I install new calipers, bleed the brakes… I remove the caliper again, and try to push/rewind it back.

Piston must move freely, without any backpressure. Do not forget, some rear callipers work like a screw…you have to turn it left/right to push/rewind it back.

I had a brand-new OEM calliper, which was already faulty. Seller always asked for return of old callipers…my bet is they refurbish, and forget to tell you because it looks shiny new…sand blasted, and repainted.

Save yourself a time & mental health, and do always double-check… especially, if your life depends on it.

Leave a Reply